“Future Forming Technology”, the Reutlingen-based forming specialist’s them this year, defines the company’s exhibition programme. With an exhibit spanning more than 1,600 m² of exhibition space, the focus is on high-speed technologies, production processes and automation solutions. The exhibition programme is completed with numerous machine premieres from all WAFIOS product ranges.

The HotBend 35 enables bending straight plastic tubes using the 3D bending process, comparable to a classic tube bending machine. In this process, the bend area is heated with hot air in the patent-pending heating system and then formed using the conventional rotary-draw bending technique. The proven TWISTER² technology is used to support the tube geometry. The HotBend 35 is WAFIOS’ response to the increasing demand in the automotive industry for weight-optimised, corrugated tubes, fluid and fuel lines.

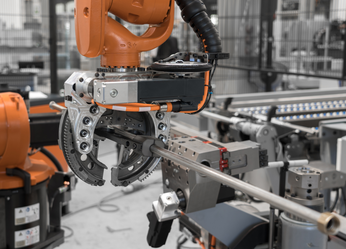

The TWISTER² robot bending machine combines flexible tube handling and the bending process in a unique overall system. Components with pre-assembled screw connections on both sides, such as those used for hydraulic lines with hose segments, can be bent efficiently by sequentially processing both sides of the tube.

“The latest machine development from WAFIOS in the field of stabiliser bar production ensures top values in output and tool life,” the company states. The RST 28 features unique, patented kinematics and reduces downtime during bending by up to 70%. It is the first tube bending machine fully tailored to the requirements of cold forming prehardened stabiliser bars with complex geometries.

wire / Hall 10 / F22/F40

Tube / Hall 5 / A21/A22