A single cruise ship contains around 400 kilometres of tube—52,000 individual sections: This is the sheer quantity that the Meyer Werft tube centre manufactures for every ship that Meyer Werft in Papenburg launches. The German shipbuilder has procured two new machines from Schwarze-Robitec. The machines use multi-stack tooling to ensure fast, safe, and high-quality processing of tubes in various dimensions, eliminating a major part of the time-consuming tool change process.

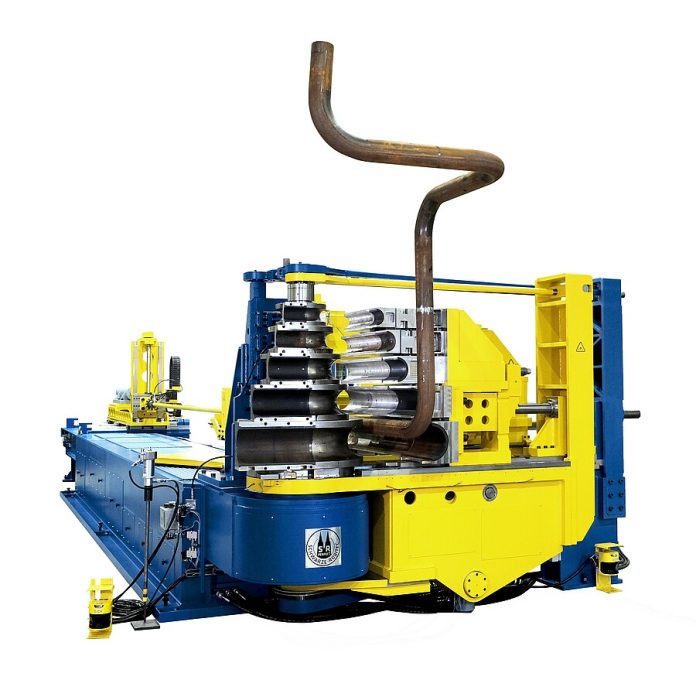

The Cologne-based tube bending expert has put two new machines into operation at Meyer Werft. A CNC 100 HD MW bends steel and stainless steel tubes with diameters ranging from 42.2 mm to 88.9 mm, and a CNC 220 HD MW handles the 114 mm to 219 mm range. Both machines are equipped with a five-stack tool tower in the respective diameter range, which allows the majority of the tools to remain set up simultaneously to bend tubes of different diameters and wall thicknesses without changing tools.

Schwarze-Robitec also supplied a semi-automatic loading device for each machine. This height-adjustable table transports the tube to the appropriate loading height, where it is fed into the machine’s index head for the subsequent bending process. This simplifies the otherwise sometimes dangerous process and represents a high safety factor for Meyer Werft. Tube / Hall 5 / E31